Si epitaxy can be performed either directly from a vapour phase (VPE) or indirectly from a solid phase (SPE). Thus, a thin heavily P-doped SPC poly-Si film can be used as a seed layer for epitaxy and it can also act as the emitter in a respective solar cell. It was reported that heavy P doping of about cm −3 enhanced SPC and resulted in a high crystal and electronic quality poly-Si material. Solid phase crystallization (SPC) of amorphous Si (a-Si) thin films is the simplest technique to obtain poly-Si at relatively low temperature (600☌) and it is commonly used for poly-Si films solar cell fabrication. These intragrain defects extending to the epilayer are found to be strongly limiting the performance of the solar cell on the AIC seed layer. The use of Al for the AIC seed layer formation results in metal contamination leading to the electronically active intragrain defects. The grain size in the AIC seed layer is larger than 10 μm, but the large grain size does not lead to better solar cells. Al-induced crystallisation (AIC) is commonly used for poly-Si seed layer fabrication. Poly-Si thin-film can be made via epitaxy on a poly-Si seed layer.

Polycrystalline silicon (poly-Si) on glass thin-film solar cells combines advantages of crystalline silicon-wafer based technology with a low material usage and large area monolithic integration typical for thin-film technologies. Silicon seed layer than vapour-phase epitaxy. It proves that solid-phase epitaxy is more suitable for the solar cell growth on the solid-phase crystallised Higher than those of the solar cell grown by vapour-phase epitaxy on the same Of 9.17 mA/cm 2, and photovoltaic conversion efficiency at 2.75% which are all Solid-phase epitaxy achieves open circuit voltage of 468 mV, short circuit current Than that in the solid-phase grown epilayer. Consequently, PC1D modelled minorityĬarrier diffusion length in the vapour-phase grown epilayer is 50% shorter

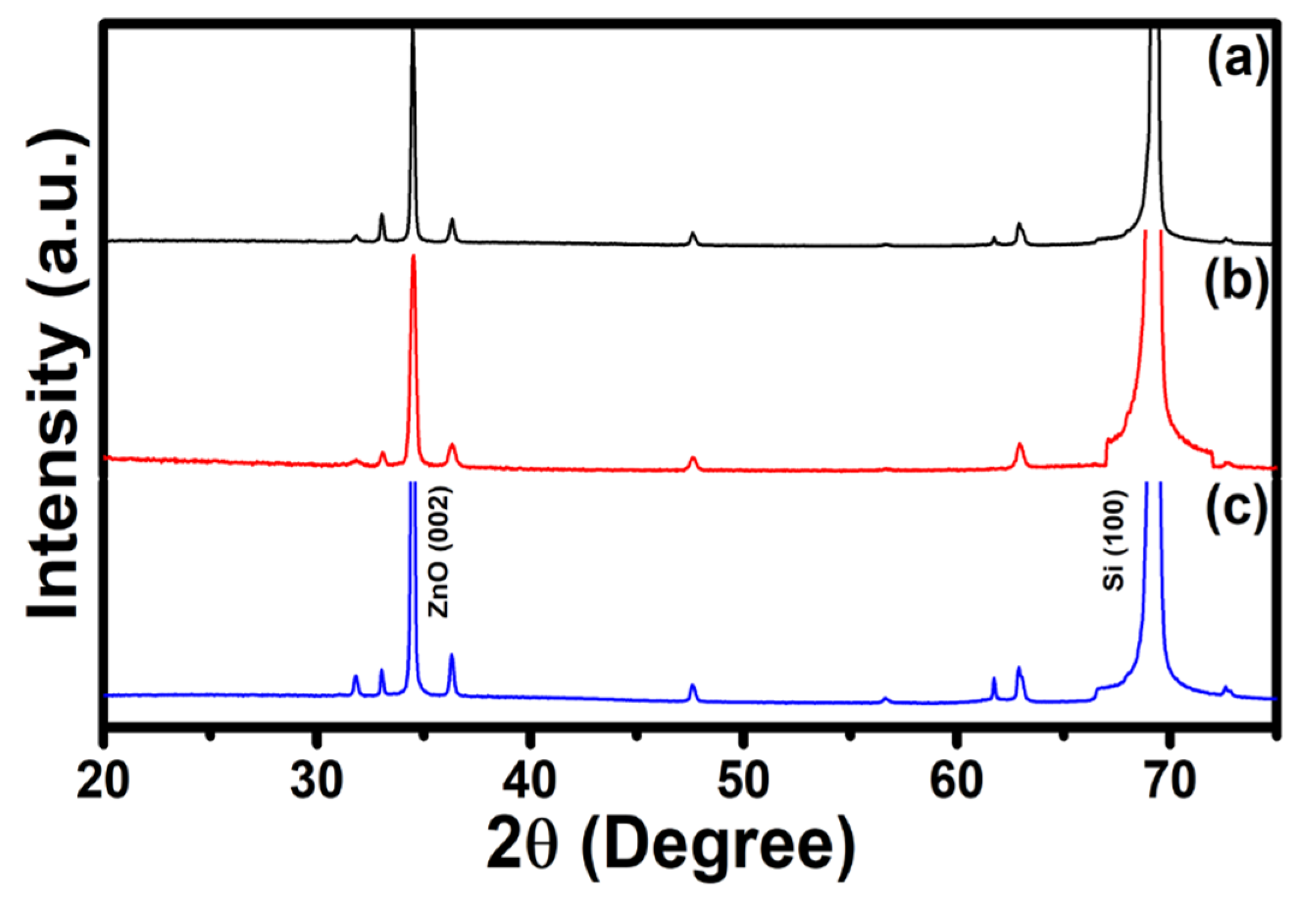

Recombination centres for free-charge carriers. Higher than in the solid-phase epitaxial sample. X-ray diffraction, scanning electron microscopy,Īnd transmission electron microscopy reveal that the density of planarĭefects (mainly on 111 plains) in the vapour-phase epitaxial sample is much Images confirm that a transfer of crystallographic information has taken placeįrom the seed layer into the epilayers. Vapour-phase and solid-phase epitaxy are used for thickening of a solid-phaseĬrystallised silicon seed layer on glass.

0 kommentar(er)

0 kommentar(er)